Our facilities are equipped with advanced manufacturing technology to meet customer demand for customized products. The ultimate goal is to ensure efficient and flexible production in a short time to meet the client’s needs and fit their requirements.

Manufacturing

Ke Cheng’s leading production equipment and professional technical personnel produce advanced products. With the use of advanced processing machine tools, automatic welding robots, scraper rollers, honing machines, machining centers and automatic test equipment, we strive to achieve higher quality products for our customers.

01

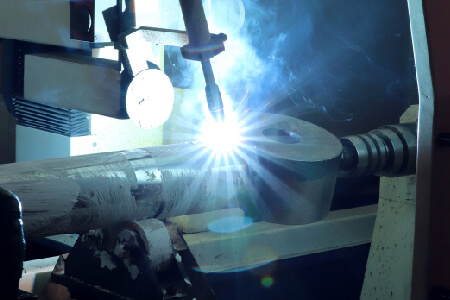

Automated Welding

The fully automatic welding system used for production ensures high-quality welds. barrel and flange are formed by welding to avoid fatigue defects caused by the weld under high pressure for a long time.

02

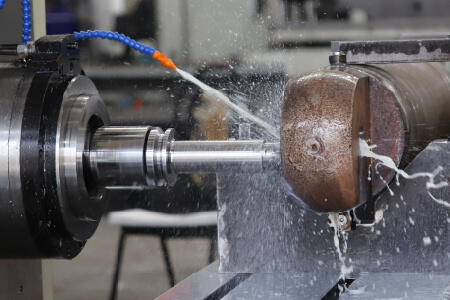

Short Cycle Complete Machining

The piston rod, cylinder, guide sleeve, piston and head are processed using a fully automatic CNC machining center / milling machine. Several manufacturing steps can be completed in the same time period, and the manufacturing cycle is short, ensuring that products are delivered to customers on time.

03

Surface Treatment

The coating we apply on the surface of the piston rod prevents corrosion and wear, ensuring abrasion resistance and long service life of the cylinder. Ke Cheng offers chrome and nichrome coatings as well as a variety of custom layer solutions.